Mono metal bullets have had a long-standing reputation for being a second best choice for long range and precision shooting. And to be honest, this used to be the case. We wanted to touch on the features that we found to make a superior, match grade, monolithic, solid copper projectile.

Features:

Lathe Turned

Having a CNC Swiss Style lathe turned bullet creates an unmatchable amount of consistency from bullet to bullet. What is a Swiss lathe? Swiss style lathes are machines used for manufacturing small precision parts under 1.25” in diameter. Many companies in the aerospace, medical, naval, and science equipment industries require extremely strict tolerances only Swiss lathes are capable of producing. In fact, our sister company, Cutting Edge Machining Solutions, has been manufacturing parts for these industries as well as many others for over 15 years.

Consistency in length, diameter, weight, and all other dimensions is crucial when shooting for accuracy, especially at longer ranges. In ELR applications, any little deviation or differences bullet to bullet will create a less than optimal shooting experience. This is why match shooters sort their cup and core bullets by weight, bearing surface length, ogive length, etc and then point and trim the meplat. Serious competitors may only end up with 200 match quality bullets out of 500 that make the grade. Our Swiss machining and stringent quality control methods virtually eliminate this need, eliminating that headache for shooters with all bullets purchased perfectly matched and usable.

Our Facility

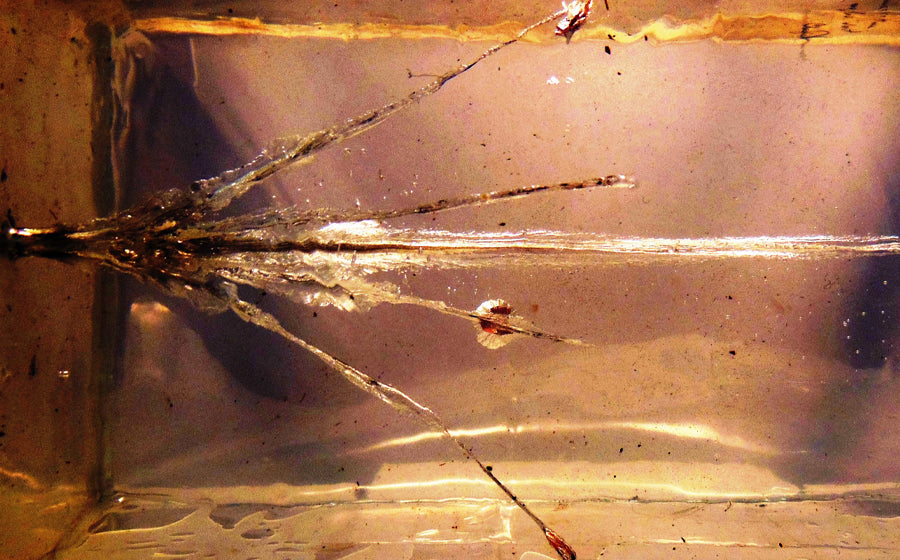

For many years, match shooters everywhere were under the impression that monolithic bullets cannot be used for precision, match shooting applications. And they were right! Monolithic bullets in the match shooting world were known for their occasional “fliers” which is something the owner of CEB, Dan Smitchko, found out early on when talking to match shooters and through initial testing. During initial testing, Dan found they were getting fliers (1 out of 5), and after talking to a well known gun smith, it was clear as to why this was happening. This knowledgeable individual explained that monolithic projectiles do not “upset” like a lead core bullet.

When you shoot a lead core bullet, the bullet actually deforms a bit, and the force of the charge makes the bullet expand to the exact size of the rifling. Why does this matter? That expansion of the bullet creates a perfect seal in the barrel which allows perfect exit from the muzzle. If gases escape around the bullet, i.e. “blow by”, it can “kick” the bullet sideways ever so slightly as it exits the barrel causing inaccuracies beyond belief. In addition to gas blow causing inaccuracy, it also creates a tremendous amount of copper fouling if using a solid copper, monolithic bullet. The hot gases heat the copper up and that can cause an excessive buildup of copper on the inside of the barrel. As you can imagine, this is a nightmare to clean. This is a common complaint we hear by our customers that have used other monolithic copper bullets.

This is what lead to Dan to think of the SealTite Band. He thought of mimicking this sealing affect by creating a narrow band around the bullet slightly larger than caliber diameter. Of course, this idea sounded slightly sketchy when he suggested it to his brother in law (now R&D specialist) Trapper and when they shot the first bullet with this feature, they definitely hid behind the reloading bench. But all went well and they found that they were no longer getting fliers.

Unknown Variables

The first bullets produced and still being produced today are the MTAC™ (Match/Tactical) and MTH™ (Match/Tactical/Hunting) bullets. These were very high BC bullets designed for match shooting and hunting applications.

A few years after the initial launch, we created the LAZER™ line, designed with a polymer tip in the tip of the bullet which allowed the use of a larger cavity for better terminal performance and also to protect the tip from damage. These bullets were also designed for long range use but were a slightly lower BC bullet than the MTH™ and MTAC™ lines, but higher terminal performance. They were marketed this way for years not realizing the biggest advantage of these bullets. But something interesting and unexpected happened upon further testing done by Applied Ballistics. We sent the AB team some of the .375 Lazers for BC testing and they reported back with some amazing results. While the BC numbers were slightly lower than the MTAC™ line just like we discovered, they pointed out the BC numbers were incredibly more consistent from bullet to bullet. Upon review of our BC testing data we saw the same thing.

Because of this discovery, the entire AB team started using the Lazer line during competitions, which ultimately lead to the 2017 King of 2 Mile victory. Winner Derek Rodgers of Applied Ballistics was using a 9.5x77 with our 400gr Lazer bullet. We are currently doing further research and testing to figure out what makes the Lazer bullets fly so well.

Interested in trying our bullets, but not sure where to start? Shoot us an email at support@cuttingedgebullets.com and we can answer any questions you might have!

Click HERE to shop our LAZER line

Click HERE to shop our MTH line

Click HERE to shop our MTAC line